Designing a compact workstation: space and thermal considerations

Designing a compact workstation requires balancing physical space, thermal performance, and component selection to maintain reliability and usable performance. This short overview highlights the key constraints of small-form-factor builds, including chassis layout, cooling strategies, component clearance, and practical choices that help avoid overheating and simplify future upgrades or maintenance.

Designing a compact workstation begins with a clear set of priorities: target use (rendering, CAD, software development), acceptable noise levels, and upgradeability. Compact cases impose strict limits on component size, orientation, and airflow; thoughtful layout choices influence motherboard form factor, GPU and CPU selection, storage arrangement, and cooling design. Accounting for clearance, cable routing, and peripheral connections at the start saves time during assembly and reduces thermal surprises later. Consider how often you will perform maintenance or upgrades and choose parts that match those expectations.

How does motherboard choice affect a compact build?

Motherboard selection is foundational for small workstations. Smaller form factors like Mini-ITX or Micro-ATX reduce footprint but also limit expansion slots and headers, affecting the number of GPUs, M.2 slots for SSDs, and fan headers. Choose a motherboard that supports required storage interfaces, sufficient VRM quality for your CPU choice, and modern firmware features like updated BIOS/UEFI for power and thermal controls. Check clearances around VRMs and chipset heatsinks so that cooling solutions and cabling do not interfere with uninterrupted airflow.

Which CPU and GPU suit small form factors?

CPU and GPU choices hinge on power, heat output, and performance targets. In a compact enclosure, favor processors with efficient performance-per-watt and GPUs designed for small form factors or low-profile cards when space is limited. Consider power draw because higher wattage parts demand stronger cooling and a capable power supply. If your workload is CPU-bound, allocate chassis space and cooling budget accordingly; for GPU-bound tasks, pick a card length and blower or dual-fan design that fits the case while providing predictable exhaust behavior.

How to plan storage and SSD layout?

Storage decisions affect both space and thermal dynamics. NVMe SSDs mounted on the motherboard or vertical risers are space-efficient but can reach high temperatures under sustained load; ensure there is airflow or heatsinking for M.2 devices. 2.5-inch SSDs provide predictable cooling and are typically simpler to mount in tight bays, while larger 3.5-inch drives demand more volume and generate more heat. Plan the layout so that hot components (GPU, NVMe SSDs) have separate airflow paths and are not clustered near intake vents.

What cooling and airflow strategies work best?

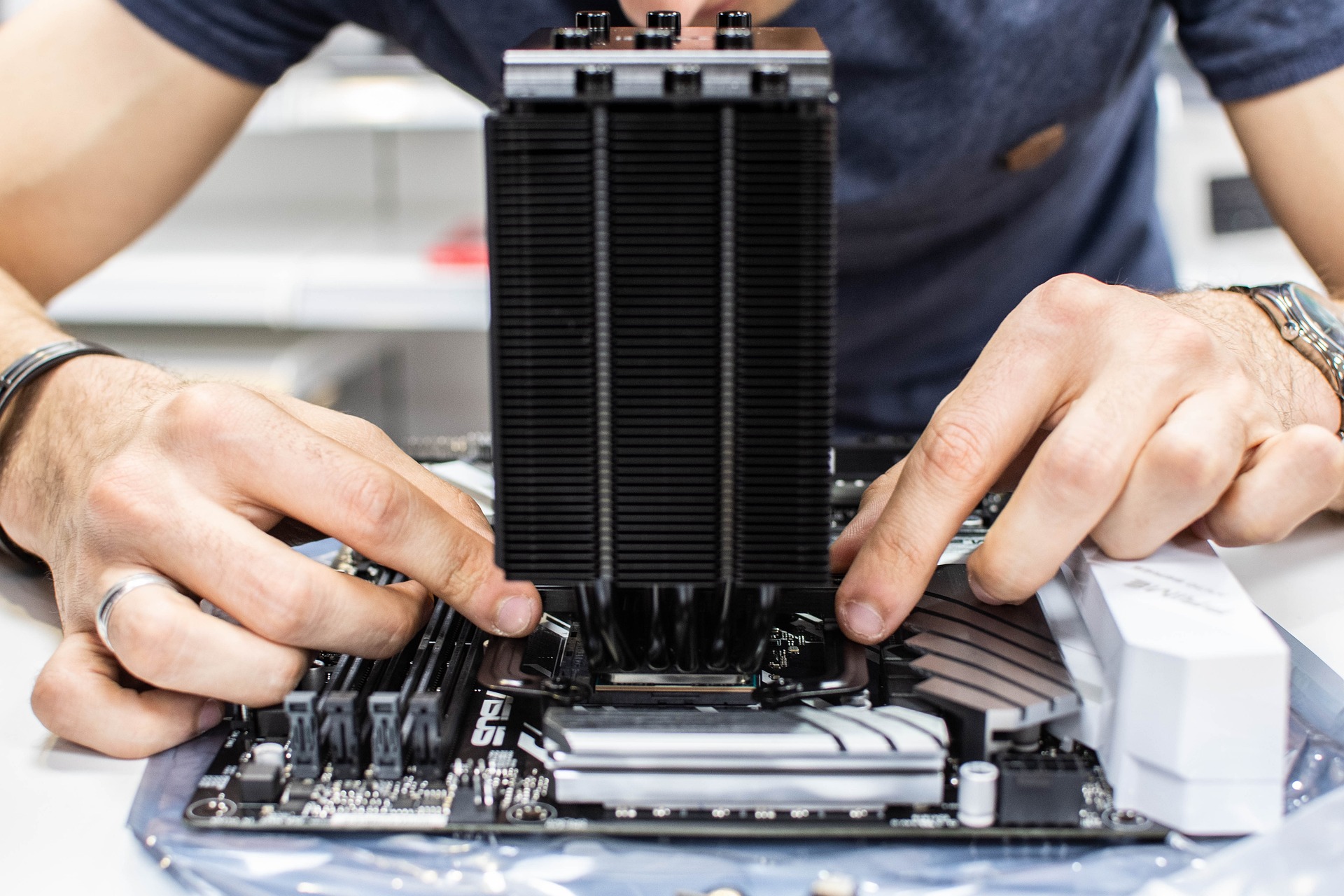

In compact systems, targeted airflow beats brute force. Create a clear intake-to-exhaust path: intake fans should draw cool air across the CPU, motherboard area, and storage, while exhaust fans remove warm air near the GPU and top vents. Use high-static-pressure fans for tight radiators or restrictive front panels and consider low-profile CPU coolers or small AIO liquid coolers if clearance permits. Monitor temperatures during representative workloads and adjust fan curves in firmware to balance noise and thermal throttling.

How to size power and manage firmware settings?

Choosing the right power supply is crucial in small builds. Consider SFX or SFX-L units for compact cases to save room without sacrificing capacity; ensure the chosen unit provides stable rails and connectors for GPU and peripherals. Confirm that the motherboard firmware supports power- and thermal-related settings like voltage offsets, fan control curves, and power limits. Proper firmware configuration can prevent overheating by enabling dynamic adjustments under load, and it also aids in troubleshooting performance or stability issues.

Assembly, upgrades, and troubleshooting tips

Plan assembly with cable management and modular components to simplify future upgrades and maintenance. Use modular power supplies and shorter cables where possible, and label connectors during assembly to speed troubleshooting. Keep spare thermal pads and a small toolkit accessible for re-seating drives or adjusting cooler mounting. For troubleshooting, isolate components — test with minimal hardware to identify thermal or power issues, and use firmware logs or software monitoring to spot sensors that report unusual voltages or temperatures.

Compact workstations demand careful choices across hardware, cooling, and layout to maintain performance and longevity. Prioritize components that match your thermal envelope and intended workloads, plan airflow paths deliberately, and account for maintenance and future upgrades during the design phase. With thoughtful compromises and measured testing, a small-form-factor workstation can deliver dependable performance in constrained spaces.